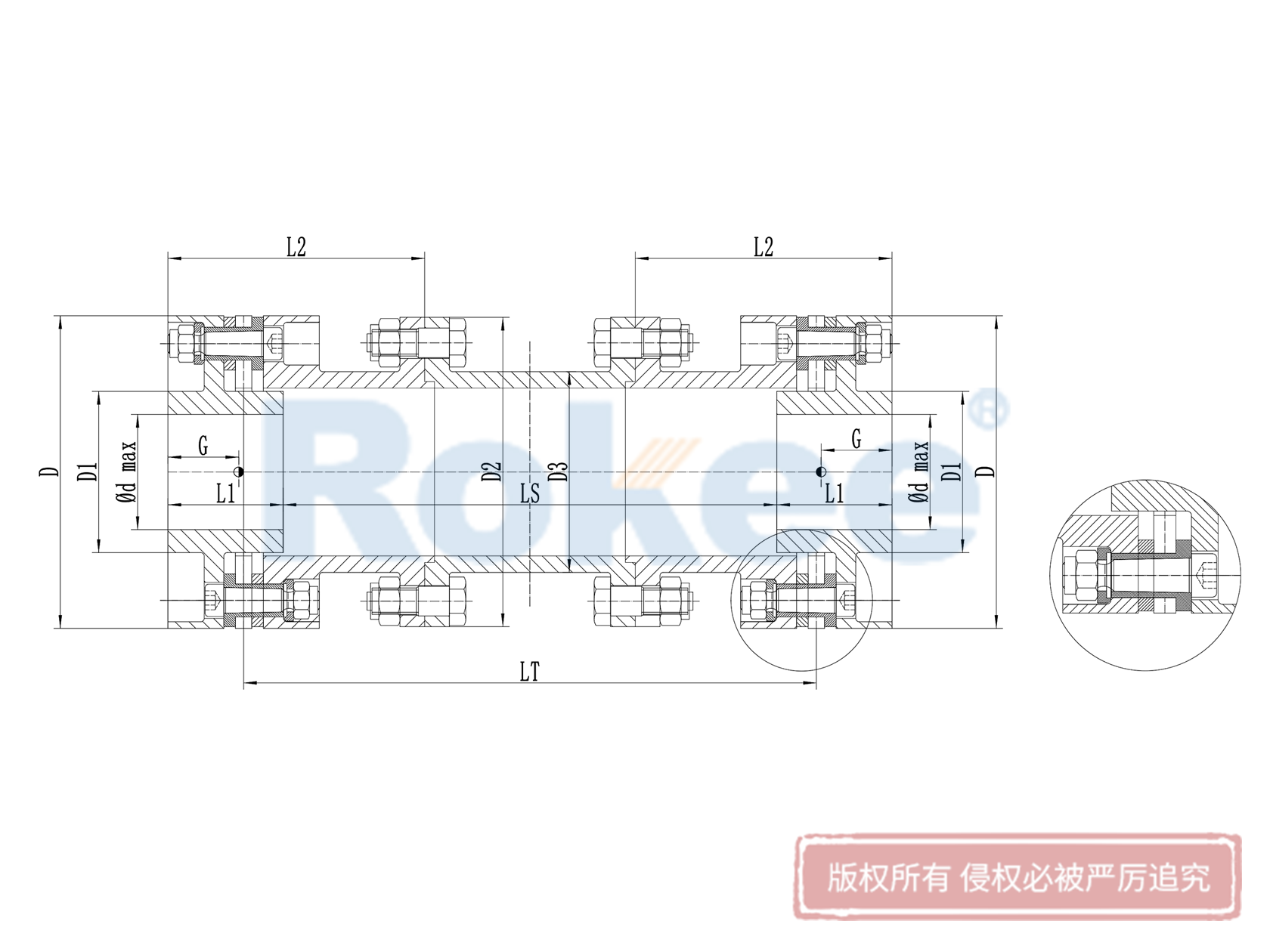

RLHD系列高速金属膜片联轴器

RLHD高速膜片联轴器适用于更高转速的使用场合,同样采用挠性组件整体装配设计,转速可达42000rpm。

| 规格 | D | D1 | D2 | D3 | d(max) | L1 | LT | LS设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD95-6 | 95 | 49 | 94 | 61 | 35 | 35 | =LS+2*24 | 按设计需求给出数据 | 40000 | 1000 | 1300 |

| RLHD125-6 | 125 | 63 | 112 | 79 | 45 | 45 | =LS+2*35 | 31500 | 2300 | 3000 | |

| RLHD145-6 | 145 | 77 | 133 | 90 | 55 | 55 | =LS+2*45 | 26500 | 4000 | 5000 | |

| RLHD175-6 | 175 | 98 | 155 | 112 | 70 | 70 | =LS+2*63 | 22000 | 6700 | 8500 | |

| RLHD205-6 | 205 | 112 | 170 | 127 | 80 | 80 | =LS+2*77 | 19000 | 10500 | 13000 | |

| RLHD220-6 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | 17300 | 14500 | 18500 | |

| RLHD250-6 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 21000 | 27000 | |

| RLHD270-6 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 26500 | 35000 | |

| RLHD295-6 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12800 | 35000 | 45500 | |

| RLHD320-6 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 41000 | 52000 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△o) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m2/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m2) | ||

| RLHD95-6 | 21.5 | 0.35 | 1.6 | 78 | 3.65 | 3.09 | 31.5 | 4.9 | 0.048 | 0.006 | (3.65/1000)*(Ls-457.2)+4.9 |

| RLHD125-6 | 25.5 | 2 | 87 | 5.6 | 8.13 | 82.6 | 8.4 | 0.11 | 0.016 | (5.6/1000)*(Ls-457.2)+8.4 | |

| RLHD145-6 | 30 | 2.4 | 105 | 8.38 | 15.7 | 160 | 13.7 | 0.201 | 0.0365 | (8.38/1000)*(Ls-457.2)+13.7 | |

| RLHD175-6 | 35.5 | 3 | 118 | 11 | 31.1 | 317 | 21 | 0.378 | 0.0812 | (11/1000)*(Ls-457.2)+21 | |

| RLHD205-6 | 38.5 | 3.8 | 125 | 15.5 | 56.1 | 571 | 30.4 | 0.623 | 0.1535 | (15.5/1000)*(Ls-457.2)+30.4 | |

| RLHD220-6 | 44.5 | 4 | 142 | 17.5 | 84.7 | 863 | 42.7 | 0.896 | 0.2692 | (17.5/1000)*(Ls-457.2)+42.7 | |

| RLHD250-6 | 51.5 | 4.6 | 160 | 22 | 138 | 1404 | 57.5 | 1.354 | 0.4711 | (22/1000)*(Ls-457.2)+57.5 | |

| RLHD270-6 | 55 | 5 | 179 | 26 | 202 | 2058 | 72.8 | 1.79 | 0.6935 | (26/1000)*(Ls-457.2)+72.8 | |

| RLHD295-6 | 60.5 | 5.6 | 190 | 31 | 297 | 2962 | 93 | 2.43 | 1.0568 | (31/1000)*(Ls-457.2)+93 | |

| RLHD320-6 | 64 | 5.8 | 200 | 35.5 | 361 | 3684 | 114 | 3.02 | 1.5153 | (35.5/1000)*(Ls-457.2)+114 | |

| 规格 | D | D1 | D2 | D3 | d1(max) | L1 | LT | LS设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD145-8 | 145 | 77 | 133 | 90 | 55 | 55 | =LS+2*45 | 按设计需求给出数据 | 26300 | 5700 | 7400 |

| RLHD175-8 | 175 | 98 | 155 | 112 | 70 | 70 | =LS+2*63 | 22000 | 9600 | 12300 | |

| RLHD205-8 | 205 | 112 | 170 | 127 | 80 | 80 | =LS+2*77 | 18500 | 15000 | 19000 | |

| RLHD220-8 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | 17200 | 20000 | 26500 | |

| RLHD250-8 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 29200 | 38200 | |

| RLHD270-8 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 38100 | 49000 | |

| RLHD295-8 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12500 | 49500 | 64000 | |

| RLHD320-8 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 59000 | 77000 | |

| RLHD350-8 | 350 | 196 | 308 | 235 | 140 | 145 | =LS+2*142 | 11000 | 81000 | 105000 | |

| RLHD390-8 | 390 | 224 | 335 | 260 | 160 | 165 | =LS+2*161 | 9800 | 115000 | 150000 | |

| RLHD435-8 | 435 | 252 | 370 | 295 | 180 | 185 | =LS+2*179 | 8750 | 168500 | 220000 | |

| RLHD498-8 | 498 | 294 | 415 | 335 | 210 | 215 | =LS+2*217 | 7500 | 250000 | 320000 | |

| RLHD545-8 | 545 | 322 | 464 | 370 | 230 | 240 | =LS+2*247 | 7000 | 330000 | 420000 | |

| RLHD595-8 | 680 | 350 | 494 | 400 | 250 | 260 | =LS+2*272 | 6450 | 410000 | 540000 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△o) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m2/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m2) | ||

| RLHD145-8 | 30 | 0.25 | 1.6 | 105 | 8.38 | 15.7 | 160 | 14 | 0.248 | 0.037 | (8.38/1000)*(LS-457.2)+14 |

| RLHD175-8 | 35.5 | 1.8 | 118 | 11 | 31.1 | 317 | 21.5 | 0.472 | 0.083 | (11/1000)*(LS-457.2)+21.5 | |

| RLHD205-8 | 38.5 | 2.4 | 125 | 15.5 | 56.1 | 571 | 31.1 | 0.792 | 0.159 | (15.5/1000)*(LS-457.2)+31.3 | |

| RLHD220-8 | 45 | 2.6 | 142 | 17.5 | 84.7 | 863 | 43.6 | 0.16 | 0.2797 | (17.5/1000)*(LS-457.2)+43.6 | |

| RLHD250-8 | 52 | 3 | 160 | 22 | 138 | 1404 | 58.7 | 1.77 | 0.4825 | (22/1000)*(LS-457.2)+58.7 | |

| RLHD270-8 | 55.5 | 3.2 | 179 | 26 | 202 | 2058 | 74 | 2.38 | 1.706 | (26/1000)*(LS-457.2)+74 | |

| RLHD295-8 | 60.5 | 2.6 | 190 | 31 | 297 | 2962 | 94.8 | 3.28 | 1.0912 | (31/1000)*(LS-457.2)+94.8 | |

| RLHD320-8 | 64 | 3.8 | 200 | 35.5 | 361 | 3684 | 117 | 4.08 | 1.56 | (35.5/1000)*(LS-457.2)+117 | |

| RLHD350-8 | 69 | 3.8 | 215 | 45 | 578 | 5887 | 149 | 5.83 | 2.36 | (45/1000)*(LS-457.2)+149 | |

| RLHD390-8 | 78.5 | 4.4 | 240 | 59 | 922 | 9396 | 208 | 8.73 | 4.125 | (59/1000)*(LS-457.2)+208 | |

| RLHD435-8 | 88 | 5 | 277 | 74 | 1493 | 15213 | 290 | 13.4 | 7.301 | (74/1000)*(LS-457.2)+290 | |

| RLHD498-8 | 99 | 5.8 | 312 | 97 | 2497 | 25443 | 420 | 20.8 | 13.912 | (97/1000)*(LS-457.2)+420 | |

| RLHD545-8 | 109 | 6.4 | 337 | 120 | 3777 | 38487 | 559 | 28.3 | 22.01 | (120/1000)*(LS-457.2)+559 | |

| RLHD595-8 | 116.5 | 7.2 | 357 | 135 | 4971 | 50657 | 690 | 36.3 | 32.215 | (135/1000)*(LS-457.2)+690 | |

| 规格 | D | D1 | D2 | D3 | d1(max) | L1 | LT | LS设计计算按457.2(18") | 许用转速(max) | 公称转矩 | 瞬时转矩(max) |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD220-10 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | 按设计需求给出数据 | 17200 | 20000 | 26500 |

| RLHD250-10 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 29200 | 38200 | |

| RLHD270-10 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 38100 | 49000 | |

| RLHD295-10 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12500 | 49500 | 64000 | |

| RLHD320-10 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 59000 | 77000 | |

| RLHD350-10 | 350 | 196 | 308 | 235 | 140 | 145 | =LS+2*142 | 11000 | 81000 | 105000 | |

| RLHD390-10 | 390 | 224 | 335 | 260 | 160 | 165 | =LS+2*161 | 9800 | 115000 | 150000 | |

| RLHD435-10 | 435 | 252 | 370 | 295 | 180 | 185 | =LS+2*179 | 8750 | 168500 | 220000 | |

| RLHD498-10 | 498 | 294 | 415 | 335 | 210 | 215 | =LS+2*217 | 7500 | 250000 | 320000 | |

| RLHD545-10 | 545 | 322 | 464 | 370 | 230 | 240 | =LS+2*247 | 7000 | 330000 | 420000 | |

| RLHD595-10 | 680 | 350 | 494 | 400 | 250 | 260 | =LS+2*272 | 6450 | 410000 | 540000 | |

| 规格 | 质点G | 角向偏差 | 轴向偏差(max) | L2 | 中间质量m | 中间转动惯量 | 中间扭转刚度 | 联轴器质量M | 扭转刚度 | 转动惯量 | 总质量(KG) |

| (mm) | (±△o) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m2/mm) | Cts-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m2) | ||

| RLHD220-10 | 45 | 0.15 | 1.6 | 142 | 17.5 | 84.7 | 863 | 45 | 1.31 | 0.248 | (17.5/1000)*(LS-457.2)+45 |

| RLHD250-10 | 52 | 2 | 160 | 22 | 138 | 1404 | 60 | 2.02 | 0.493 | (22/1000)*(LS-457.2)+60 | |

| RLHD270-10 | 55.5 | 2.1 | 179 | 26 | 202 | 2058 | 78 | 2.73 | 0.721 | (26/1000)*(LS-457.2)+78 | |

| RLHD295-10 | 60.5 | 2.4 | 190 | 31 | 297 | 2962 | 97 | 3.77 | 1.123 | (31/1000)*(LS-457.2)+97 | |

| RLHD320-10 | 64 | 2.4 | 200 | 35.5 | 361 | 3684 | 125 | 4.71 | 1.615 | (35.5/1000)*(LS-457.2)+125 | |

| RLHD350-10 | 69 | 2.4 | 215 | 45 | 578 | 5887 | 155 | 6.78 | 2.425 | (45/1000)*(LS-457.2)+155 | |

| RLHD390-10 | 78.5 | 2.8 | 240 | 59 | 922 | 9396 | 215 | 10.2 | 4.239 | (59/1000)*(LS-457.2)+215 | |

| RLHD435-10 | 88 | 3.2 | 277 | 74 | 1493 | 15213 | 305 | 15.8 | 7.463 | (74/1000)*(LS-457.2)+305 | |

| RLHD498-10 | 99 | 3.8 | 312 | 97 | 2497 | 25443 | 435 | 24.7 | 14.223 | (97/1000)*(LS-457.2)+435 | |

| RLHD545-10 | 109 | 4 | 337 | 120 | 3777 | 38487 | 578 | 33.8 | 22.543 | (120/1000)*(LS-457.2)+578 | |

| RLHD595-10 | 116.5 | 4.6 | 357 | 135 | 4971 | 50657 | 710 | 43.5 | 32.915 | (135/1000)*(LS-457.2)+710 | |

RLHD联轴器可应用于高速运转场合,转速可大于40000转以上,是高速发电设备,燃气和蒸汽涡轮机,涡轮压缩机,离心给油泵,船舶推进系统的很好选择。

此系列产品采用可分离中间接管设计,可以不必拆卸与挠性组件相连的周边法兰直接安装和拆卸,并且可以很方便地进行绝缘、碳纤维轻量化等变形设计。

本系列联轴器膜片组采用多角形高柔性及小风阻设计,可以承受径向和轴向对中偏差,非常适用于热膨胀(轴向补偿)较大的场合及高转速应用的产品。

- 标签:

- 联轴器

荣基工业科技(江苏)有限公司

销售专线:13505289959(微信)

公司座机:0511-85519688

销售QQ:3362645520

企业邮箱:Rokee@Rokee.com

公司地址:镇江高新技术产业开发区留脉路1号

手机站

手机站  微信咨询

微信咨询