Cement Grinding Heavy Tooth Diaphragm Coupling

Rokee? is a Cement Grinding Heavy Tooth Diaphragm Coupling Supplier from China, customized cement grinding heavy tooth diaphragm coupling according to the drawings which provided by the customer, selling chinese national standard cement grinding heavy tooth diaphragm coupling, support export, due to excellent quality, complete technical services and superior cost performance, Rokee? industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

The Drum Gear Coupling is a specially designed advanced Gear Coupling. Its outer teeth are made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

ROD Curved-tooth Gear Coupling is one of the transmission products with core technology independently developed by Rokee and has established and reported corporate technical standards in the country. By combining with the standard coupling technology of advanced countries such as Japan and Germany, we optimized many detailed dimensions, and adopted the toothed design with a large pressure angle and short shaft design for the shaft hole, which reduces the length-diameter ratio, and has a more compact structure and excellent speed performance.

The bolts of similar types are standardized and the parts are universal. Compared with the national standard couplings, our Toothed Couplings can transfer more torque, with greatly reduced mass and small moment of inertia. It meets the European explosion-proof requirements and the comprehensive performance is greatly advanced. We highly recommend you to choose our Crown Gear Couplings for better transmission performance.

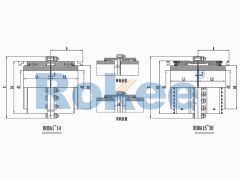

RODA Drum Gear Coupling

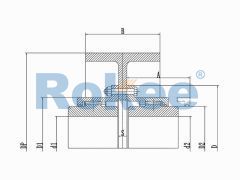

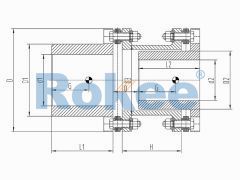

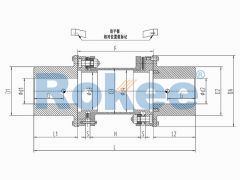

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.RODT Indirect Tube Drum Gear Coupling

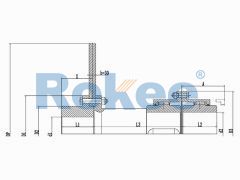

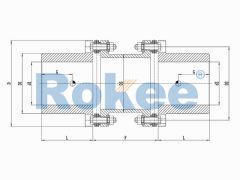

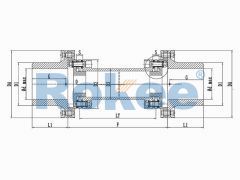

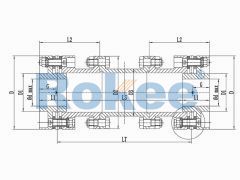

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.RODX Intermediate Shaft Drum Gear Coupling

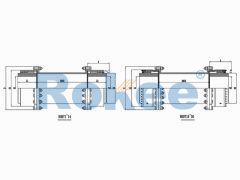

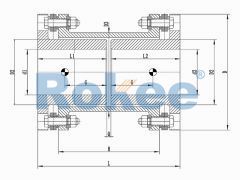

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.RODP Brake Disc Drum Gear Coupling

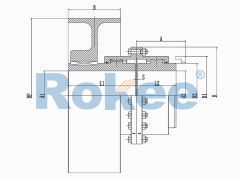

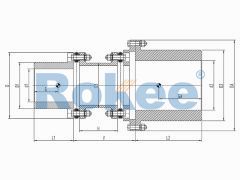

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.RODF Split Brake Disc Drum Gear Coupling

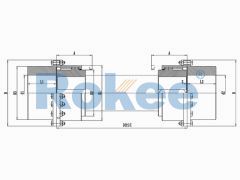

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.RODW Brake Wheel Drum Gear Coupling

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.

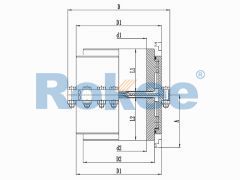

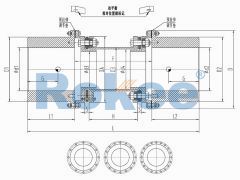

GICL Drum Gear Coupling

GICL drum gear coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.GICLZ Drum Gear Coupling

Half of the GICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.GIICL Drum Gear Coupling

GIICL drum gear coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.GIICLZ Drum Gear Coupling

Half of the GIICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.GCLD Drum Gear Coupling

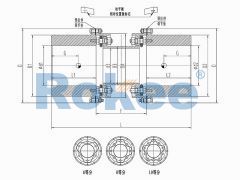

GCLD drum gear coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required.NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.WG Drum Gear Coupling

The overall characteristics of WG drum gear coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking.WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking.WGT Drum Gear Coupling

WGT drum gear coupling is designed with indirect tube, suitable for long distance torque transfer.WGC Drum Gear Coupling

WGC drum gear coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.WGJ Drum Gear Coupling

WGJ drum gear coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.

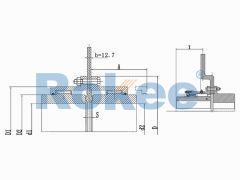

Diaphragm Coupling is a kind of high-performance metal Flexible Coupling, which compensates axial and angular displacements by the deformation of elastic diaphragm while transferring torque. It features with compact structure, large transmission torque, long service life, maintenance-free, high temperature resistance, acid and alkali resistance, and corrosion resistance, suitable for shafting transmission in high temperature, high speed and corrosive environment.

Rokee's RL series Steel Laminae Couplings are independently developed on the basis of high-quality products from Europe and Japan. It has smaller volume, larger torque of the same type, more reasonable proportioning size, large compensation range, light weight and small moment of inertia. Special elastic gasket design is adopted in the hole connection part of bolt and diaphragm group, which greatly reduces the stress concentration in the hole edge part, eliminates the tear loss of diaphragm, and extends the service life. With modular design, the coupling assembly is simple and its maintenance and replacement are quick. The performance far exceeds the national standard JM series products, which are widely used in fan systems, steam turbine units and other important industrial fields.

RLM Small Single Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.RLMD Small Double Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.RLA Standard Single Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications, but cannot compensate for radial deviation.RLAD Standard Double Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.RLAR Single Shaft Sleeve Reverse-mounting Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.RLARD Double Shaft Sleeve Reverse-mounting Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.RLAF Large & Small Shaft Mounted Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.RLAT Super Long Wheelbase Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.RLQF Flange Type Quick Installation Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.RLQU Improved Flange Quick Installation Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.RLHD High Speed Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.

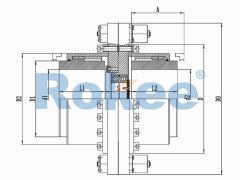

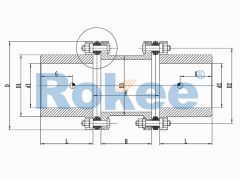

JMIIJ Diaphragm Coupling

JMIIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.JMII Diaphragm Coupling

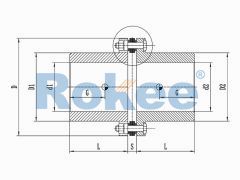

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.JMIJ Diaphragm Coupling

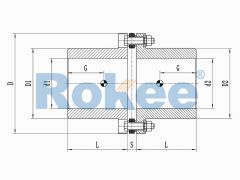

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.JMI Diaphragm Coupling

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.

« Cement Grinding Heavy Tooth Diaphragm Coupling » Post Date: 2023/10/17

URL: http://games.editingderrick.cn/en/blog/cement-grinding-heavy-tooth-diaphragm-coupling.html

Tags: Diaphragm Couplings, Elastic Diaphragm Couplings, Flexible Diaphragm Couplings, Double Diaphragm Couplings,

- Diaphragm Couplings For Cement Mills

- Small Diaphragm Couplings

- Diaphragm Coupling Of Wire Drawing Machine

- Sales of Flexible Diaphragm Couplings

- Single Diaphragm Coupling Processing

- Heavy Duty Diaphragm Coupling Factory

- Conical Sleeve Type Double Diaphragm Coupling

- Flexible Diaphragm Coupling Working Principle

- Diaphragm Coupling For Paper Making

- Circular Diaphragm Coupling